Blog: In The Beginning...How Silage Oxygen Barriers Came To Be.

By Felipe X. Amaro, PAS, Ph.D.

Global Technical Support and R&D, Passion Ag

The evolution of silage cover technologies reflects significant advancements in preserving silage quality and reducing top spoilage. In the early days, silage was often stored in pits or piles without any form of cover, leaving it exposed to the elements. This exposure led to great losses due to weather damage, animal attacks, and most notably oxygen infiltration, which promotes spoilage through aerobic microbial deterioration. The lack of protection resulted in high dry matter (DM) losses, poor fermentation, and nutrient degradation. With the advance of technology and the need to preserve silage yield and nutrients to maintain high levels of animal performance, Passion Ag recognized the necessity for high quality oxygen barriers, now established as the gold standard in terms of silage protection. Passion Ag products are manufactured using premium quality materials and the latest production technology to guarantee minimum oxygen ingress and ensure maximum return on investment.

The early days: Dirt and Crop Residues

The first attempts to cover silage involved using readily available materials—dirt and crop residues. Farmers used soil to cover silage piles, creating a barrier that protected their silages against air and animals. This method had numerous downsides. Besides letting water through, dirt as a covering material was heavy, difficult to manage, and introduced contaminants into the silage. Crop residues like straw or corn stalks were also used but were less effective at excluding oxygen and allowed extensive spoilage and poor fermentation.

Polyethylene Plastics: A Big Step Forward

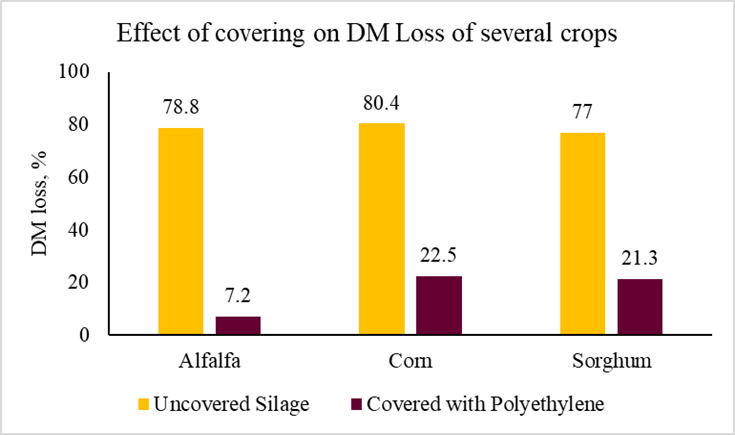

Real improvements came in the 1950s with the introduction of polyethylene plastics as silage covers, which drastically reduced the DM losses of silages. Markedly, there was widespread adoption and improvement in silage preservation because these materials were lightweight, easy to apply, and provided better barrier against the elements than dirt or crop residues. However, standard polyethylene plastic still allowed for oxygen permeability, leading to spoilage and poorer fermentation in the outermost layers of silage. This issue encouraged the search for more advanced oxygen barrier materials.

Oxygen Barriers: The Next Best Thing

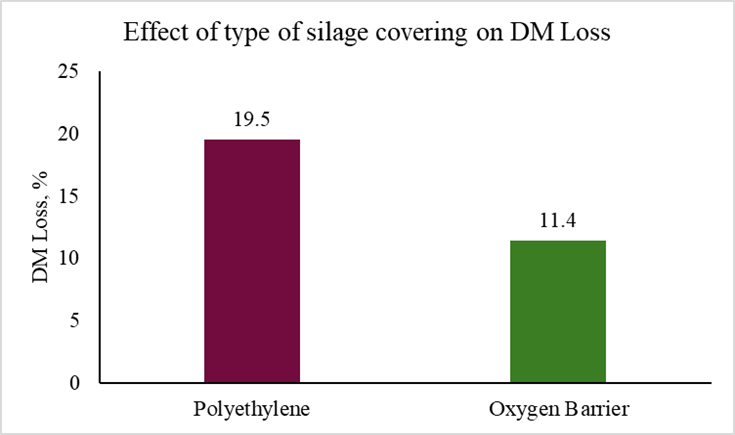

In the early 2000s, oxygen barriers made with different raw materials (resins) were the next step in silage cover technology. They offer greater resistance to oxygen infiltration than standard polyethylene plastic and can be incorporated into multilayered silage covers to improve their effectiveness. These multilayered films helped improve fermentation and reduce spoilage, particularly at the surface of the silage pile/bunker where exposure to air was greatest. However, not all raw materials are made the same, have the same quality standards or the same level of oxygen barrier protection. Passion Ag oxygen barriers are exclusively made with topnotch quality raw materials and the most recent and advanced technologies with the highest oxygen barrier level which drastically reduces oxygen ingress, leading to minimal to no top spoilage and excellent preservation of silage yield and quality. Besides ensuring proper fermentation throughout the silage pile or bunker, reducing dry matter loss and preserving nutrients at greater extents than other silage covers, Passion Combo, our lead seller product, combines Passion Yellow (1.8mil oxygen barrier) and a white-on-white film (5mil polyethylene) in single roll for a tight cling and excellent toughness. It has a unique folding pattern that allows for covering silage piles and bunkers with a one-pull movement which minimizes labor and time, while the white-on-white film provides protection against the UV light and maximum reflectiveness. The ability to virtually block oxygen associated with the easiness of application and UV protection makes Passion Combo the most effective product for reducing top spoilage, enhancing silage quality, and saving time and labor required for silage covering which allows farmers to protect their feed yields and maximize nutritional value for their livestock.

Adapted from Bolsen et al. 1993. Rate and extent of top spoilage losses in horizontal silos. J. Dairy Sci., 76 (1993), pp. 2940-2962.

Adapted from Wilkinson and Fenlon, 2014. A meta-analysis comparing standard polyethylene and oxygen barrier film in terms of losses during storage and aerobic stability of silage. Grass Forage Sci., 69 (2014), pp. 385-392.

About the Author:

Felipe Xavier Amaro, Ph.D., PAS,

Felipe is an expert in animal and crop nutrition, with a strong focus on innovation, sustainability, and on-farm profitability.

Based in Gainesville, Florida, Felipe leads Global Technical Support and Research & Development at PASSION AG.With a deep understanding of the science behind nutrition and a practical approach to farm performance, he plays a key role in driving product development and supporting customers worldwide.

Felipe holds a Ph.D. from the University of Florida and is a certified Professional Animal Scientist (PAS), reflecting his dedication to scientific excellence and real-world results.